JET band saw repair

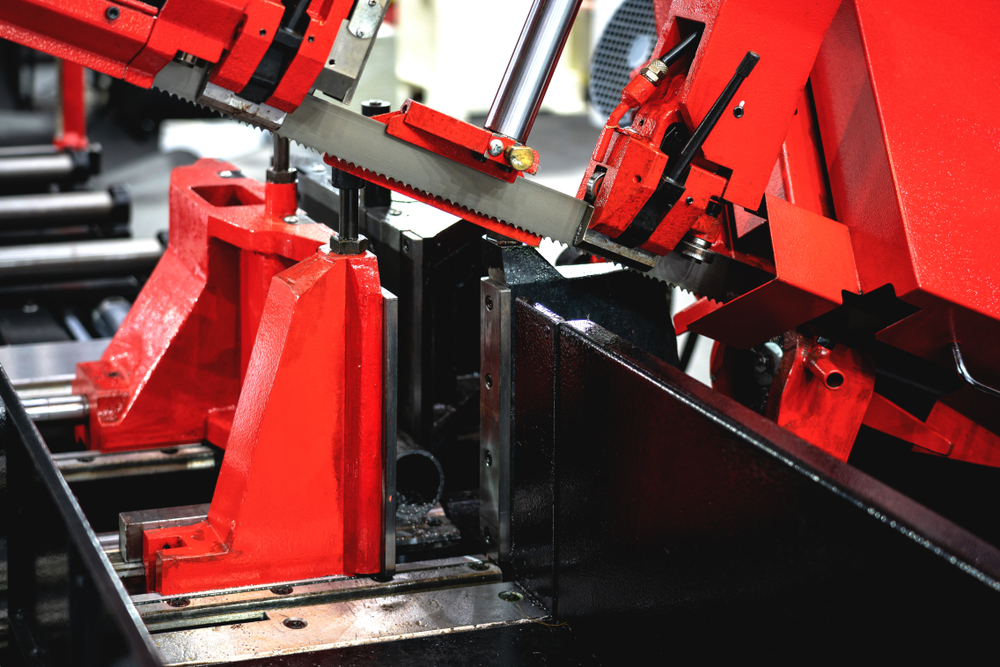

JET Band Saw Repair

When your JET band saw slows down, production cannot afford to wait. S I Machine Services responds fast with expert JET band saw repair sharpened by 20+ years in the field. Hands-on, brand-savvy, and always on the ready: we restore accuracy, reliability, and peace of mind with every fix.

We service these major industrial band saw brands