Amada Band Saw Repair

Amada Band Saw Repair

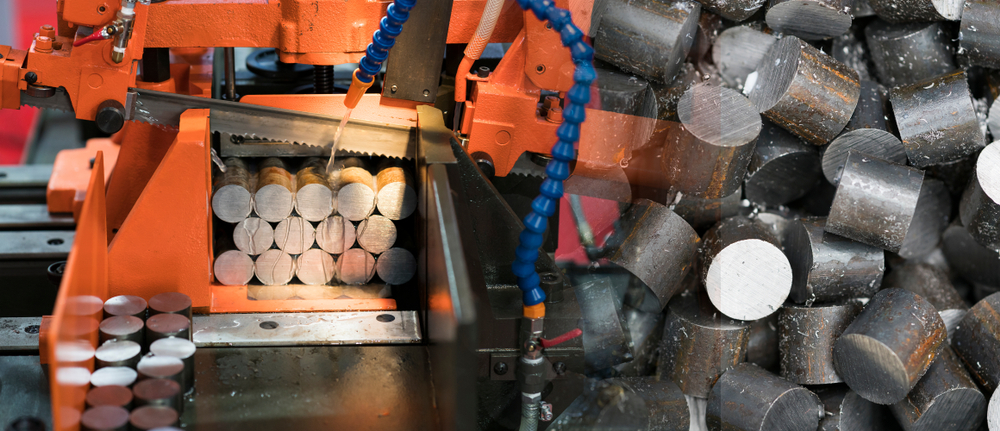

Are your Amada saws giving you problems? At S I Machines Services, our Amada band saw repair combines trust, expertise, and decades of hands-on experience to restore your equipment and keep your production running seamlessly.

We service these major industrial band saw brands